If you’re thinking about starting a shisha charcoal business, investing in a high-quality shisha charcoal making machine is essential. A reliable machine will help you produce high-quality shisha charcoal efficiently and effectively. However, with so many different models and manufacturers to choose from, it can be challenging to know which machine to purchase. In this article, we’ll provide you with some tips on how to choose a suitable shisha charcoal making machine.

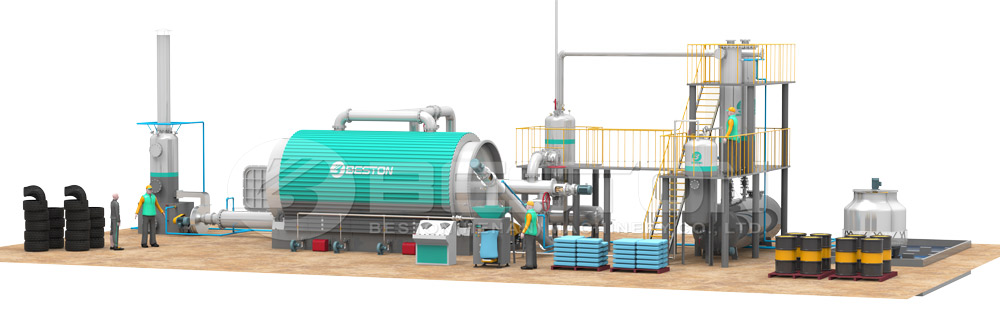

High-quality Beston Shisha Charcoal Making Machine

Consider the Production Capacity

When it comes to purchasing a shisha charcoal making machine, production capacity is one of the most critical factors to consider. Your machine’s capacity will determine how much shisha charcoal you can produce in a given amount of time. The production capacity of shisha charcoal machines can vary greatly, from as little as a few kilograms per hour to several hundred kilograms per hour. Therefore, it’s essential to determine your production needs before making a purchase.

Quality and Durability

Another important factor to consider is the quality and durability of the machine. Look for a shisha charcoal making machine that is built to last, with high-quality components and materials. A durable machine will help you avoid costly repairs and replacements down the line. Additionally, a reliable machine will ensure consistent and high-quality shisha charcoal production. Investors contact this biochar machine manufacturer – Beston Group to get the suitable machine.

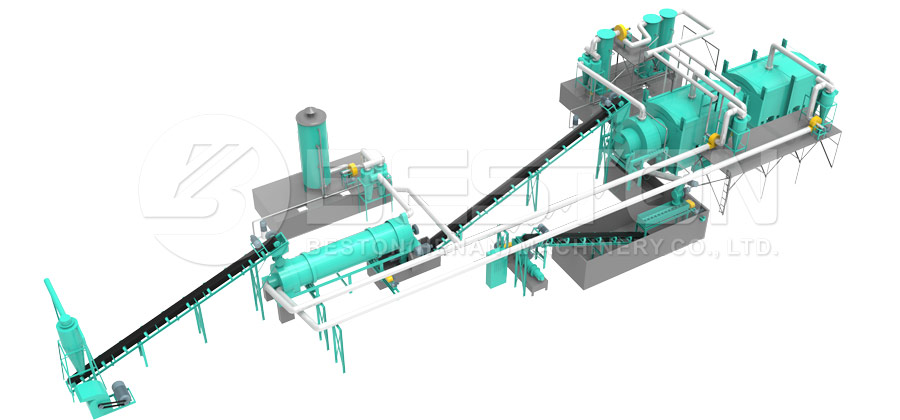

Shisha Hookah Charcoal Making Machine for Sale

Ease of Use

A shisha charcoal making machine should be easy to operate, with clear instructions and minimal maintenance requirements. Make sure to choose a machine that you and your team can quickly learn to use and maintain. If the machine is too complicated, it may lead to frustration and decreased productivity.

Price

Price is another crucial factor to consider when purchasing a shisha charcoal making machine. The cost of the machine will depend on its capacity, quality, and features. Determine your budget before shopping around, and look for machines that offer the best value for your money. Keep in mind that a lower-priced machine may not be the best long-term investment if it requires frequent repairs and maintenance. View the https://bestonmachinery.com/biomass-charcoal-making-machine/.

Manufacturer Reputation

Finally, it’s essential to choose a shisha charcoal making machine from a reputable manufacturer. Look for manufacturers with a proven track record of producing high-quality, durable machines. Read reviews and ask for recommendations from other shisha charcoal business owners to ensure you’re making a wise investment.