Oil sludge, a byproduct of the oil and gas industry, poses significant environmental challenges. Traditional disposal methods often fall short in addressing these concerns, leading to the exploration of advanced technologies. Thermal desorption has emerged as a highly effective method for treating oil sludge, offering a sustainable and efficient solution. This comprehensive guide delves into the intricacies of thermal desorption plant, exploring its principles, applications, benefits, and considerations in the context of oil sludge treatment.

I. Understanding Oil Sludge

Before delving into thermal desorption, it’s crucial to understand the composition and challenges posed by oil sludge. This section provides an overview of oil sludge, detailing its formation, components, and environmental impact. The complex nature of oil sludge, containing hydrocarbons, solids, and water, necessitates advanced treatment methods to mitigate its adverse effects on ecosystems.

II. Principles of Thermal Desorption

Thermal desorption operates on the principle of using heat to volatilize and separate contaminants from the solid matrix. This section delves into the fundamental principles of thermal desorption, covering the processes of vaporization, separation, and condensation. Understanding the science behind thermal desorption is essential for grasping its effectiveness in treating oil sludge by waste oil sludge pyrolysis plant.

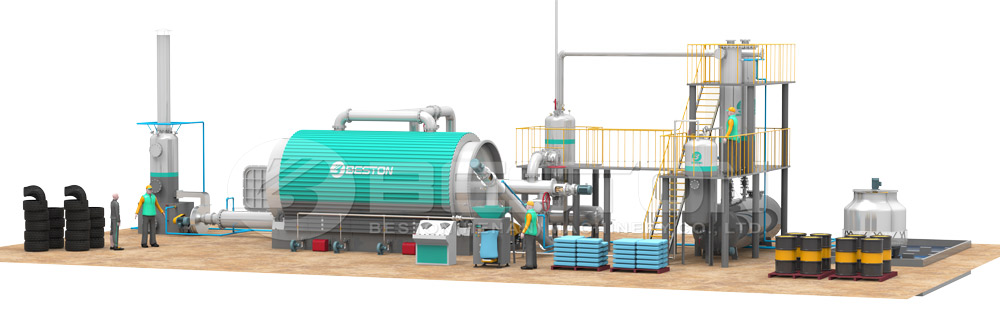

III. Types of Thermal Desorption Technologies

Several thermal desorption technologies are available for treating oil sludge, each with its unique features and advantages. This section explores common methods such as indirect-fired rotary kilns, direct-fired thermal desorption units, and fluidized bed systems. A comparative analysis of these technologies sheds light on their suitability for different scales and compositions of oil sludge.

IV. Benefits of Thermal Desorption

Thermal desorption offers a myriad of benefits in the treatment of oil sludge. From efficient recovery of hydrocarbons to reduced environmental impact, this section discusses the advantages of using thermal desorption as a remediation method. Additionally, the recovered hydrocarbons can often be recycled or reused, contributing to the economic viability of the overall process.

V. Applications in Oil Sludge Treatment

The versatility of thermal desorption makes it suitable for various applications in oil sludge treatment. This section explores its use in cleaning oil storage tanks, remediating contaminated soil, and treating oily waste streams. Case studies and real-world examples illustrate the successful application of thermal desorption in diverse scenarios within the oil and gas industry.

VI. Considerations and Challenges

While thermal desorption is a powerful technology, it is essential to acknowledge considerations and challenges associated with its implementation. Factors such as energy consumption, treatment efficiency, and regulatory compliance need to be carefully addressed. This section provides insights into mitigating challenges and optimizing the performance of thermal desorption systems.

VII. Environmental Impact and Regulatory Compliance

Environmental sustainability is a critical aspect of oil sludge treatment, and adherence to regulatory standards is imperative. This section examines the environmental impact of thermal desorption, including emissions and waste disposal considerations. An overview of global regulatory frameworks ensures a comprehensive understanding of the compliance requirements for thermal desorption projects.

VIII. Cost Analysis and Economic Viability

A thorough cost analysis is essential for evaluating the economic viability of thermal desorption projects. This section explores the factors influencing the overall cost, including equipment, energy consumption, and maintenance. Additionally, it discusses the potential economic benefits, such as recovered hydrocarbons and reduced long-term environmental liabilities.

IX. Future Developments and Innovations

As technology continues to evolve, so does the landscape of oil sludge treatment. This section explores ongoing research, innovations, and potential future developments in thermal desorption technology. Advancements in automation, process optimization, and integration with other remediation methods are likely to shape the future of oil sludge treatment.

X. Case Studies and Success Stories

Real-world examples of pyrolysis oil plant provide valuable insights into its practical application and success. This section highlights case studies where thermal desorption has been effectively employed to treat oil sludge, showcasing the versatility and efficiency of the technology across different settings and challenges.

Conclusion

In conclusion, thermal desorption stands as a transformative technology in the realm of oil sludge treatment. Its ability to efficiently separate contaminants from the solid matrix, coupled with environmental and economic benefits, positions it as a sustainable solution for the oil and gas industry. As we strive for more responsible and efficient waste management practices, thermal desorption emerges as a key player in mitigating the environmental impact of oil sludge and advancing towards a more sustainable future.