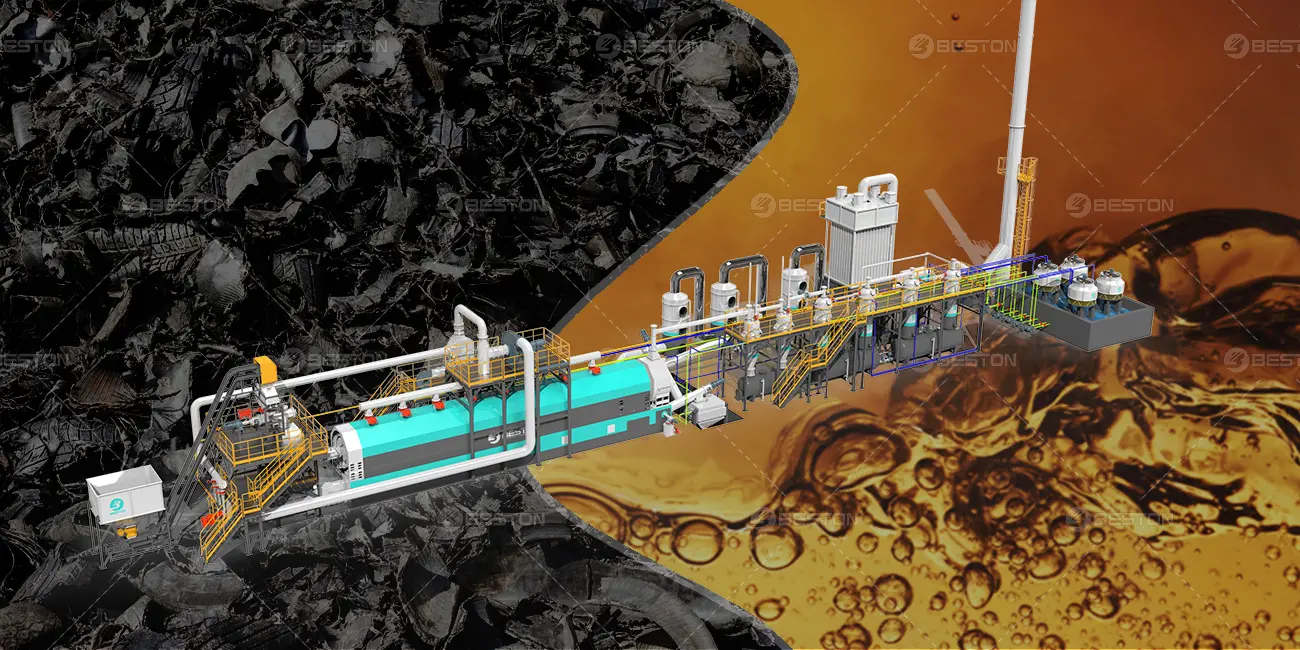

The tyre pyrolysis process is a complex thermal decomposition of tyres in the absence of oxygen. The internal reaction mechanism within a tyre pyrolysis reactor is crucial to understanding how waste tyres are converted into valuable products such as oil, gas, and carbon black. The reactor operates under specific temperature and pressure conditions that influence the chemical breakdown of the tyre components. This article delves into the internal reaction processes that occur within a waste tire pyrolysis plant and the factors that impact the efficiency and output of the system.

The Pyrolysis Process in a Tyre Pyrolysis Reactor

Pyrolysis refers to the thermal decomposition of organic materials at high temperatures, typically between 350°C and 700°C, in the absence of oxygen. In the case of a tyre pyrolysis reactor, the feedstock, consisting of waste tyres, is subjected to these high temperatures in a controlled environment. The tyres are primarily composed of rubber, steel, and other organic materials such as oils and carbon black. The primary objective of the pyrolysis reactor is to break down these complex materials into simpler, more valuable products.

The process begins when the tyres are heated in the reactor, causing the polymer chains in the rubber to break apart. This thermal degradation results in the formation of various gaseous, liquid, and solid products. The distribution of these products depends on several factors, including the temperature, pressure, and the type of tyre being processed.

Chemical Reactions During Pyrolysis

The internal reactions in the pyrolysis reactor can be categorized into three main stages: depolymerization, cracking, and condensation.

- Depolymerization: The first stage of the pyrolysis process is depolymerization, where the high temperature causes the long polymer chains in the rubber to break down into smaller molecules. This reaction results in the formation of volatile compounds, such as light hydrocarbons, which are the precursors for the production of pyrolysis oil and gas.

- Cracking: Once the polymer chains are broken down, the smaller molecules undergo further cracking. This step is essential for breaking the complex hydrocarbons into even smaller, more volatile compounds. Cracking reactions lead to the production of gaseous hydrocarbons such as methane, ethylene, and acetylene, which can be used as fuel or further processed for other applications.

- Condensation: As the pyrolysis products cool, condensation occurs, leading to the formation of liquid oil. This liquid is composed of a mixture of hydrocarbons, including aliphatic and aromatic compounds. The liquid oil is a valuable by-product of the pyrolysis process and can be refined into usable fuels.

- Solid Residue Formation: The remaining solid residue after pyrolysis is carbon black, which is a valuable material used in various industries, such as rubber production, ink manufacturing, and plastics. The amount of carbon black produced depends on the feedstock and operating conditions of the reactor.

Economic Considerations: Pyrolysis Reactor Cost

The efficiency and performance of a tyre pyrolysis reactor are directly linked to its cost-effectiveness. While the cost of tyre pyrolysis plant can vary depending on the scale and technology of the plant, the potential for high returns on investment makes it an attractive option for waste tyre recycling. The reactor’s design, automation, and capacity all influence the initial investment, but these factors also determine the reactor’s operational efficiency and the overall yield of pyrolysis products.

In terms of economic viability, a well-optimized tyre pyrolysis reactor can generate multiple revenue streams. The oil produced during the pyrolysis process can be refined into fuel or sold as a chemical feedstock. The gas can be used as an energy source to power the reactor, reducing external energy costs. Carbon black, as a high-demand by-product, can also be sold to industries, further enhancing the profitability of the plant.

Factors Influencing the Reaction Mechanism

Several factors affect the internal reaction mechanism within a tyre pyrolysis reactor, influencing both the yield and the quality of the products produced. Want to get a reliable reactor manufacturer? Please contact Beston Group.

- Temperature: Temperature plays a critical role in the pyrolysis process. Higher temperatures promote the cracking of larger molecules, resulting in a higher yield of gas and oil. However, excessively high temperatures can lead to the over-cracking of valuable compounds, reducing the overall quality of the liquid products. Optimal temperature control is essential for maximizing the efficiency of the reactor and ensuring the desired product distribution.

- Pressure: The pressure inside the reactor also influences the pyrolysis reactions. In general, higher pressures favor the production of liquid products, while lower pressures lead to a higher yield of gas. The pressure can be adjusted depending on the specific needs of the pyrolysis process, allowing for greater control over the final product composition.

- Feedstock Composition: The type of tyre used as feedstock can significantly impact the pyrolysis process. Tyres consist of rubber, steel, and other additives, each of which behaves differently under pyrolysis conditions. The rubber component is the primary source of hydrocarbons, while the steel is generally removed as a by-product. The presence of other materials, such as plastic or synthetic fibres, can also affect the yield and composition of the pyrolysis products.

- Heating Rate: The rate at which heat is applied to the tyres can influence the reaction kinetics. Rapid heating tends to favor the production of gas, while slower heating allows for more complete depolymerization and a higher yield of liquid oil. The heating rate must be carefully controlled to balance the production of gas, oil, and solid residue.

Conclusion

The internal reaction mechanism of a tyre pyrolysis reactor is a multi-stage process that involves the thermal degradation of tyre components into valuable products. The depolymerization, cracking, and condensation reactions within the reactor are influenced by various factors, including temperature, pressure, and feedstock composition. Understanding these mechanisms is essential for optimizing the pyrolysis process and improving the efficiency of the reactor. Additionally, the cost-effectiveness of the tyre pyrolysis plant depends on the reactor’s design, operational efficiency, and the ability to generate profitable by-products. As technology advances, the internal reaction mechanisms within these reactors will continue to improve, further enhancing their economic and environmental benefits.