The growing demand for sustainable and eco-friendly energy sources has positioned charcoal production from agricultural waste as a viable alternative to traditional methods. Among various organic materials, palm waste has emerged as a significant resource for producing high-quality charcoal, particularly from palm kernel shells. This shift toward utilizing palm waste offers several economic and environmental benefits, including waste reduction, energy production, and sustainable resource management. By harnessing the potential of advanced charcoal machines, businesses can optimize production processes, meet market demands, and drive profitability.

Economic Benefits of Charcoal Production

The palm industry, particularly in tropical regions, generates vast quantities of waste material, including palm kernel shells, which are typically discarded or left to decay. Converting these byproducts into valuable products like charcoal opens up new avenues for revenue generation. Charcoal made from palm kernel shells, for example, is highly regarded for its efficiency and sustainability, which makes it an attractive option for both domestic and international markets.

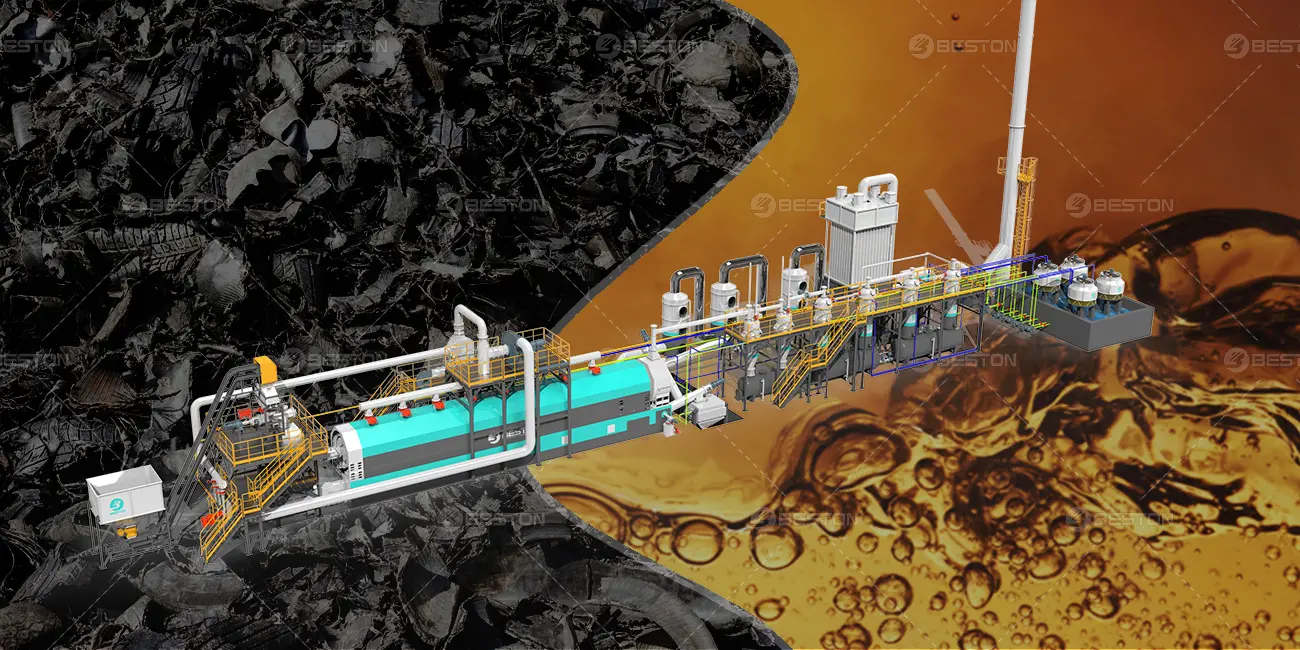

The process begins with the use of a specialized charcoal manufacturing machine, which facilitates the pyrolysis of palm kernel shells. This method involves heating the shells in a controlled environment, breaking down their organic components into carbon-rich charcoal. The machine’s efficiency and precision play a crucial role in maximizing the yield of charcoal while minimizing energy consumption and operational costs.

By establishing production facilities in regions abundant with palm plantations, companies can create a cost-effective supply chain. This process not only adds value to agricultural waste but also provides an additional income stream for local communities involved in palm cultivation. The byproducts of this process, such as charcoal dust and biochar, can be repurposed for various industrial applications, further enhancing the profitability of the venture.

Market Demand for Sustainable Charcoal

Global trends indicate a significant shift towards eco-friendly alternatives in various industries, especially in energy, agriculture, and manufacturing. Palm kernel shell charcoal is increasingly sought after due to its low emissions and high calorific value, making it an ideal fuel for industrial processes and cooking. Additionally, palm kernel shell charcoal is used in the production of activated carbon, which finds applications in water filtration, air purification, and even medicine.

The demand for sustainable charcoal is especially prominent in regions that have stringent environmental regulations. Countries are continuously seeking carbon-neutral alternatives to replace traditional coal and wood charcoal. Palm kernel shell charcoal, being a renewable resource, is an attractive option for industries looking to reduce their environmental footprint while maintaining efficiency.

Furthermore, palm kernel shell charcoal is highly competitive in the global market due to its affordable production cost and versatile applications. The low-cost raw material, coupled with the advanced technologies employed in biomass pyrolysis plant operations, ensures that the final product is both cost-effective and of high quality.

Environmental Impact and Sustainability

The environmental benefits of producing charcoal from palm waste are significant. Palm kernel shells, when left unchecked, can contribute to pollution and deforestation. By utilizing this waste material, the process effectively reduces the environmental burden associated with palm oil production.

The sustainable nature of palm kernel shell charcoal production is enhanced by the fact that it is a form of waste-to-energy technology. Palm kernel shells are often burned inefficiently or left to decompose, releasing harmful greenhouse gases into the atmosphere. However, by converting these shells into charcoal, harmful emissions are significantly reduced. The process itself is designed to capture and store the released gases, which can be used for energy generation, making the process not only carbon-neutral but potentially even carbon-negative when optimized.

Additionally, the high energy efficiency of palm kernel shell charcoal makes it an environmentally preferable option compared to traditional fuels. Its dense carbon content allows it to burn hotter and longer, reducing the need for frequent replenishment and minimizing fuel consumption.

Technological Advancements in Charcoal Production

The development of more efficient charcoal machines has played a pivotal role in enhancing the commercial viability of charcoal production from palm waste. Modern machines are designed to optimize the pyrolysis process, ensuring higher yields and reducing the time required for production. These machines also allow for better control over temperature, pressure, and airflow, which are critical factors in determining the quality of the final charcoal product.

Moreover, automation and smart technologies are increasingly integrated into charcoal machine operations, improving overall efficiency and reducing labor costs. The ability to scale up production using automated systems is particularly beneficial for businesses looking to meet large-scale demand while maintaining high-quality standards. To obtain advanced equipment, please contact Beston Group Co., Ltd.

The future of charcoal production from palm waste will likely see further innovations, such as the use of renewable energy sources to power charcoal machines or the development of biochar applications for soil improvement. These advancements will not only enhance the profitability of the business but also contribute to a more sustainable and environmentally conscious approach to energy production.